CNC Turning Services

Get quality custom parts for prototyping and production, fast and cost-effective.

Materials

| Aluminum | Stainless Steel | Steel | Other Metals | Plastics |

| 2024 | 303 | 1018 | Copper 101 | ABS |

| 5052 | 304/304L | 1215 | Copper 260 | Acetal (Delrin) |

| 6061 | 316/316L | 4130 | Copper 360 | Polycarbonate |

| 6063 | 410 | 4140 | Copper C110 | PET |

| 7050 | 416 | 4140PH | Copper C932 | PA66 (Nylon) |

| 7075 | 420 | 4340 | Inconel 718 | PEEK |

| 440C | A36 | Titanium (Grade 2) | PTFE (Teflon) | |

| 15-5 | Titanium (Grade 5) | Polypropylene | ||

| 17-4 | Zinc Alloy | POM | ||

| 18-8 | PTFE | |||

| Nitronic 60 (218 SS) | PMMA |

* We can source any other materials on request.

CNC Turning Finishes

Standard. With no secondary processing.

Anodizing is an electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish.

Aluminum is ideally suited to anodizing, although other nonferrous metals, such as magnesium and titanium, also can be anodized.

The bead blasting process shoots a blasting media – beads – under high pressure at a part to clean, polish, or roughen it to the desired finish.

A bead blast finish can clean a part’s surface, remove cosmetic defects, create a uniform surface with a dull, satin, or rough texture, and even harden a part’s surface and enhance its durability. It also prepares a part for paint and other coatings.

Bead media includes steel, glass, quartz sand, garnet, etc.

Manufacturers apply bead blasting for materials like metals, plastics, rubber, and glass.

Electrophoresis is the process of applying paint to parts by passing an electric current through the paint solution and parts immersed in it.

In many ways, this process is similar to electroplating. It is also called electrocoating, e-coating, electrophoretic coating, and electrophoretic painting.

Electrophoresis is suitable for aluminum alloy, zinc alloy, and stainless steel. It makes the parts present various colors and keep the metallic luster, and enhances the surface performance with high corrosion resistance.

Electroplating is the process of applying a thin layer of one metal to a part by passing a positively charged electrical current through a solution containing dissolved metal ions (anode) and a negatively charged electrical current through the part to be plated (cathode).

The aim is to improve the overall quality of the part. Some benefits include improving corrosion resistance, wear resistance, appearance, lubricity, and solderability.

Steels, nickel, copper-based alloys, and other metals are readily electroplated.

Polishing is the process of creating a shiny and smooth surface, either through physical rubbing of the part or by chemical interference.

The process enhances the aesthetic appeal, prevents corrosion, improves cleanability, and reduces adhesion of the parts.

It produces a surface with significant specular reflection but can reduce diffuse reflection in some materials.

Polishing works excellent with many metals, including aluminum, brass, stainless steel, and steel.

Powder coating is a process of applying a free-flowing, dry, thermoset, or thermoplastic powder to the surface of a part which is then cured under heat or with ultraviolet light.

The process creates a strong, wear- and corrosion-resistant layer that is more durable than standard painting methods.

It works perfectly on metals, plastics, and other materials.

Our CNC Turning Capabilities

| Metric | Imperial | |

| Max. Part Size | Ø1000 x 1500 mm | Ø393.70 x 590.55 in |

| Tolerance | ±0.025 mm | ±0.001 in |

Tolerances: ISO 2768 unless otherwise specified.

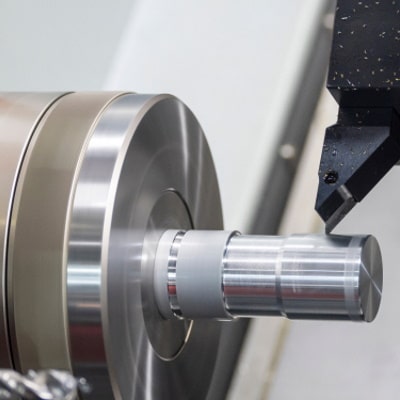

What is CNC Turning?

CNC turning is a manufacturing process that rotates a workpiece around its axis at high speed while a fixed cutting tool is held against it to remove material to make the final part.

Advantages of CNC Turning

Ability to create round profiles

High Precision

Parts can be made in a matter of hours, whereas other methods may take days (or weeks) to complete

High efficiency

Wide range of material options

CNC Turning FAQs

CNC turning is used for creating a variety of parts, including auto parts, knobs, tubes, gears, toy parts, flywheels, crankshafts, hubs & disc cams. It is most often used to manufacture parts for automotive, aerospace, medical, and other industries.

A CNC Turning Center performs a turning type operation. CNC lathes, or turning centers, have tooling mounted on a turret which is computer-controlled. CNC Turning is a process in manufacturing where workpieces are rotated as various tools are used to remove material and create the desired shape.

Rough turning removes as much material as possible without a focus on accuracy and surface finish, getting the workpiece close to the desired shape. Finish turning “finishes” the process, producing the desired smoothness and accuracy.

CNC lathes are most often only 2 axis machines with one spindle. They also don’t have high production capabilities and typically don’t have a protective enclosure around the machine. CNC turning centers are more advanced versions of CNC lathes with up to 5 axes and more versatility in cutting ability. They also offer the ability to produce higher volumes and usually integrate milling, drilling, and other capabilities.

In addition to using turning tools, a CNC turning center can also be equipped with rotating cutters such as end mills or drills, which allows for greater freedom in machining, such as having the ability to handle asymmetrical features in parts. This increases production speed and efficiency, cost-effectiveness and safer operations. Several aspects of turning that are unique and different from milling, include the ease of achieving radial symmetry, high precision due to mounting part in chuck, and good surface finish.