Die Casting Services

Get quality custom parts for prototyping and production, fast and cost-effective.

Die Casting Materials

| Aluminum | Magnesium | Zinc | |

| A356 | 384 | AZ91D | Zamak-2 |

| 360 | A384 | AM60B | Zamak-3 |

| A360 | 413 | AS41B | Zamak-5 |

| A380 | A413 | Zamak-7 | |

| 383 | B390 | Zamak-8 | |

| A383 | C443 | Zamak-12 |

* We can source any other materials on request.

Die Casting Finishes

Standard. With no secondary processing.

Anodizing is an electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish.

Aluminum is ideally suited to anodizing, although other nonferrous metals, such as magnesium and titanium, also can be anodized.

The bead blasting process shoots a blasting media – beads – under high pressure at a part to clean, polish, or roughen it to the desired finish.

A bead blast finish can clean a part’s surface, remove cosmetic defects, create a uniform surface with a dull, satin, or rough texture, and even harden a part’s surface and enhance its durability. It also prepares a part for paint and other coatings.

Bead media includes steel, glass, quartz sand, garnet, etc.

Manufacturers apply bead blasting for materials like metals, plastics, rubber, and glass.

Electrophoresis is the process of applying paint to parts by passing an electric current through the paint solution and parts immersed in it.

In many ways, this process is similar to electroplating. It is also called electrocoating, e-coating, electrophoretic coating, and electrophoretic painting.

Electrophoresis is suitable for aluminum alloy, zinc alloy, and stainless steel. It makes the parts present various colors and keep the metallic luster, and enhances the surface performance with high corrosion resistance.

Electroplating is the process of applying a thin layer of one metal to a part by passing a positively charged electrical current through a solution containing dissolved metal ions (anode) and a negatively charged electrical current through the part to be plated (cathode).

The aim is to improve the overall quality of the part. Some benefits include improving corrosion resistance, wear resistance, appearance, lubricity, and solderability.

Steels, nickel, copper-based alloys, and other metals are readily electroplated.

Polishing is the process of creating a shiny and smooth surface, either through physical rubbing of the part or by chemical interference.

The process enhances the aesthetic appeal, prevents corrosion, improves cleanability, and reduces adhesion of the parts.

It produces a surface with significant specular reflection but can reduce diffuse reflection in some materials.

Polishing works excellent with many metals, including aluminum, brass, stainless steel, and steel.

Powder coating is a process of applying a free-flowing, dry, thermoset, or thermoplastic powder to the surface of a part which is then cured under heat or with ultraviolet light.

The process creates a strong, wear- and corrosion-resistant layer that is more durable than standard painting methods.

It works perfectly on metals, plastics, and other materials.

Die Casting Capabilities

| Metric | Imperial | |

| Max. Part Size | 1200 x 1600 x 1000 mm | 47.24 x 62.99 x 39.37 in |

| Min. Wall Thickness | 1.2 mm | 0.05 in |

| Max. Part Weight | 60 kg | 132 lb |

Tolerances: ISO 8062 ST5

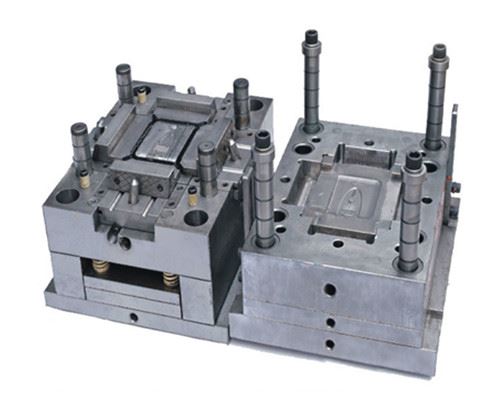

What is Die Casting?

Die casting is the manufacturing process of making relatively complex parts by injecting molten metal into custom-made steel molds. It’s the most cost-effective way to produce high volumes of metal parts with excellent surface finish and dimensional accuracy.

Advantages of Die Casting

Suited for complex metal parts

Excellent surface quality

Fast production cycle times

Recyclable choice of material

High dimensional accuracy

Die Casting FAQs

Metal injection molding (MIM) and die casting are similar manufacturing techniques. They both use metals and alloys in the fabrication of parts. The major difference is the metal types used in either method. Die casting uses mostly aluminum and other non-ferrous metals. In contrast, metal injection molding uses steel, iron, nickel, and other MIM alloys.

Yes, reusing old molds can reduce the die-cast mold cost. Of course, this is only possible when the old mold has a reasonable frame. However, if possible, you should avoid using an old worn-out mold. Instead, when the mold is at the end of its service life, make a replica mold.

Die casting is an automated casting process. It takes a while to create the mold. But the mold can solidify aluminum alloy quickly. And as it is an automated process, the machine can manufacture many units without taking any break. Therefore, die casting is a fast process, especially when you are manufacturing a vast number of parts.

1 Try to simplify the design. Too many intricate details tend to increase the cost. Therefore, removing intricate details that are not critical for structural integrity and the part’s overall performance is better.

2 Though die casting can easily fabricate thin-walled components, reducing or avoiding them is better. Furthermore, since these thin walls often require machining; hence they attract additional fabrication costs.

3 Desists from unnecessary tolerances. Too many precision requirements lead to an increased tooling cost.

4 Try to avoid features and undercuts that are difficult to access with a 3 or 4-axis CNC machine.

Aluminum die casting is one of the most cost-effective metal die casting processes. Though the die casting tooling needs more time, you can create thousands of units with one mold. The more you produce, the less becomes your unit price. Aluminum is much cheaper than stainless steel and slightly more expensive than carbon steel.